Commercial Garage Door Cable Installation Hacks to Improve Durability and Performance

Heavy weights, frequent use, and harsh environments are all things that commercial garage doors are made to withstand. However, the cables—one of the most important components of their operation—are frequently disregarded. To safely raise and lower large doors, these steel wires are used in conjunction with springs. If they malfunction, operations cease, safety hazards increase, and repair costs rapidly increase.

The good news? By using smart installation hacks and maintenance strategies, you can significantly improve the durability and performance of commercial garage door cables.

Why Garage Door Cables Matter in Commercial Settings

Cables for commercial garage doors do much more than just raise doors. They

In manufacturing buildings, loading docks, fire stations, and warehouses, support large, heavy doors.

When used in conjunction with torsion or extension springs, maintain balanced movement.

Avoid safety risks by preventing the door from suddenly collapsing.

Lessen the load on motors and openers to increase their longevity.

Installing and maintaining cables correctly is crucial because of their weight and frequent use in business settings.

Signs of Worn or Failing Commercial Garage Door Cables

Before diving into installation hacks, it’s important to recognize when cables need repair or replacement. Common warning signs include:

Fraying or visible wear along the cable strands.

Rust or corrosion weakening the metal.

Uneven door movement, such as tilting to one side.

Snapped cable causing immediate door failure.

Loud grinding noises from the pulley or drum.

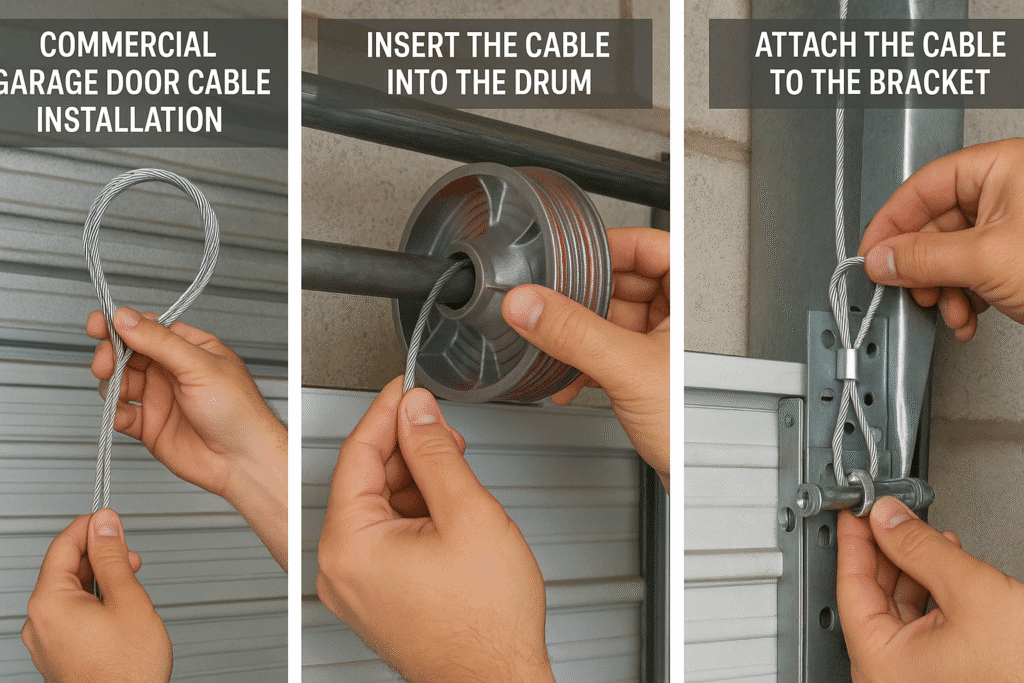

Best Practices for Commercial Garage Door Cable Installation

To optimize longevity and functionality, experts suggest these crucial tips:

1. Select the Appropriate Cable Type

For heavy-duty sectional doors, torsion spring cables are ideal.

Extension spring cables are appropriate for smaller, lighter doors.

Safety cables: Offer contingency protection to avoid harm in the event that a spring fails.

For corrosion resistance, always choose stainless steel or galvanized wires.

2. Proper Sizing and Tensioning

Measure cable length accurately based on door height and spring system.

Avoid overtightening—too much tension can snap cables prematurely.

Ensure both sides have equal tension for balanced operation.

3. Reinforced Cable Drums and Anchors

Use heavy-duty drums capable of handling higher torque.

Secure anchors with industrial-grade fasteners.

Check that grooves in drums are smooth to prevent fraying.

4. Lubrication and Rust Prevention

Apply a light machine oil or silicone-based spray to prevent corrosion.

Avoid heavy grease, which attracts dust and dirt.

Schedule lubrication at least twice a year in high-use facilities.

5. Double-Cable System for Extra Safety

For critical environments like fire stations, consider a redundant cable system. If one cable fails, the backup prevents sudden door collapse.

6. Use High-Tensile Strength Cables

Investing in reinforced, aircraft-grade steel cables provides longer service life, especially for oversized industrial doors.

7. Professional Installation & Inspection

Commercial doors weigh hundreds of pounds, making DIY installation dangerous. Hiring a certified technician ensures:

Correct drum winding.

Proper alignment with springs.

Long-term operational reliability.

Maintenance Hacks to Extend Cable Life

Even the strongest cables need regular care. Here’s how to extend their lifespan:

Inspect cables quarterly for wear, rust, or loose ends.

Keep cables clean by removing debris and dust.

Balance the door regularly to reduce strain on cables.

Replace cables in pairs to ensure equal performance.

Schedule annual tune-ups with a commercial garage door company.

Cost of Commercial Garage Door Cable Replacement

Cable size, material, and labor all affect price.

Replacement wires often cost between $50 and $120 each.

Strong galvanized wires: between $100 and $250 each

$200 to $500 for professional installation (labor + parts)

Although same-day or emergency service could be more expensive, repair costs are frequently lower than downtime in commercial operations.

When to Upgrade Instead of Replace

If your facility has older doors with outdated spring and cable systems, consider upgrading. Modern cable systems:

Offer higher weight capacities.

Use rust-resistant technology.

Provide built-in safety redundancies.

Work seamlessly with smart openers.

Conclusion

The foundation of secure and effective operations is provided by commercial garage door cables. You may significantly increase longevity and performance by using smart installation tips, such as selecting the appropriate cables, keeping the tension perfect, lubricating frequently, and purchasing high-quality materials.

Heavy-duty commercial doors require professional installation and maintenance; however, simple checks can be completed internally. Prioritize cable health to safeguard your building, machinery, and staff; it’s a simple investment that will pay out in the long run in terms of efficiency and safety.

Pingback: 2025 Garage Door Bracket Replacement: Proven Repair Tips

Pingback: 24/7 Garage Door Repair Fast Emergency Service